PVD is Good, but CVD is Necessary

In the world of metal cutting, not all coatings are created equal. While PVD (Physical Vapor Deposition) excels in milling and finishing, it falls short when facing the extreme heat and abrasion of heavy-duty turning on steel and cast iron.

For insert manufacturers targeting the heavy machining market, Chemical Vapor Deposition (CVD) is not an option—it is a necessity. Only CVD can grow the thick, chemically bonded α-Al2O3 (Alpha Alumina) layers required to survive temperatures above 1000°C.

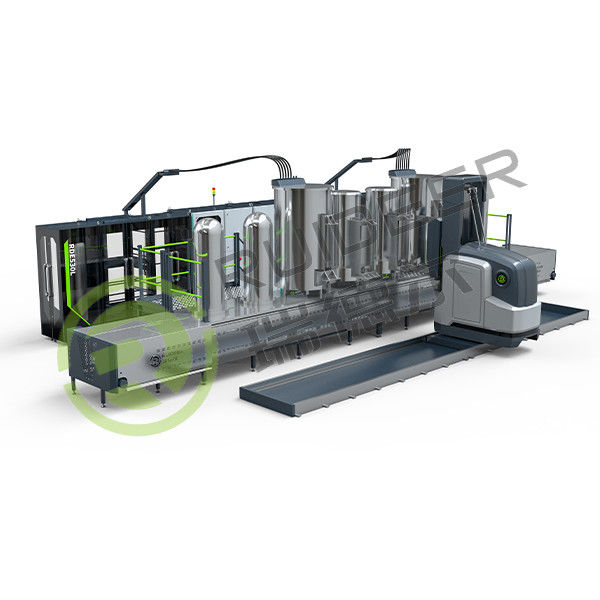

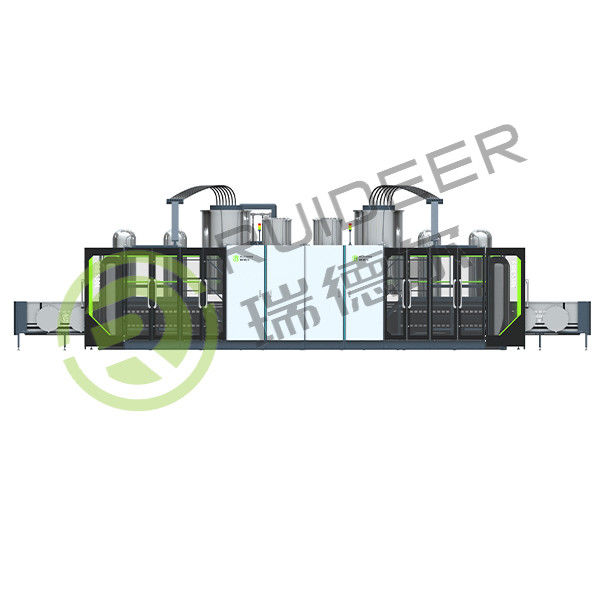

Introducing the Ruideer RDE530L CVD Coating Furnace—engineered to give your inserts the ultimate "thermal armor."

Unmatched Capacity & Efficiency

The RDE530L is a production beast designed for high-volume insert manufacturers.

1. Dual-Station Design for Continuous Output

Efficiency is money. The RDE530L features a Dual Workstation configuration with 2 Hot Wall Deposition Reactors.

- How it works: While one reactor is in the coating cycle, the other can be cooled, unloaded, and reloaded. This minimizes downtime and maximizes throughput.

- Reactor Durability: The reactor cylinders are made of centrifugally cast heat-resistant alloy steel (φ500mm × 1500mm, 15mm thick), guaranteeing a service life of up to 200 furnace cycles.

2. Massive Throughput

Don't let coating be your bottleneck.

- Loading Capacity: With a 37-tray setup (Tray Diameter: φ375mm), a single batch can process approximately 12,500 inserts (based on IC 12.7mm standard size).

- Result: High daily output to meet urgent delivery schedules.

3. The "Crown Jewel" of Coatings: αAl2O3 & MT-TiCN

Our system is optimized to deposit the most critical multi-layer structures:

- TiN (Base Layer): For adhesion and leak detection (gold color).

- MT-TiCN (Medium Temp): For extreme hardness and abrasive wear resistance.

- αAl2O3 (Alpha Alumina): The ultimate heat barrier. It prevents crater wear during high-speed machining of steels and cast irons.

- Result: A coating thickness of 5-20 microns with superior adhesion strength compared to PVD.

4. Complete Turnkey Solution (Safety & Environment)

CVD involves hazardous gases (TiCl4, H2). Ruideer takes safety seriously.

- Process Control: Fully automated gas delivery (AlCl3 generator) and temperature control.

- Environmental Compliance: We offer a comprehensive Exhaust Neutralization System (Scrubber) as a turnkey option. It efficiently treats corrosive byproducts (like HCl) into harmless salts, ensuring your factory meets strict environmental standards.

Key Technical Specifications (RDE530L)

| Parameter |

Specification |

| Furnace Structure |

Dual Workstations (2 Reactors) |

| Reactor Size |

φ500mm × 1500mm (Centrifugally Cast Alloy) |

| Max. Working Temp |

1100°C |

| Capacity (IC 12.7) |

~12,500 pcs / batch |

| Heating Power |

55 KVA |

| Coating Types |

TiC, TiN, MT-TiCN, αAl2O3 |

Ideal Applications

- Heavy Turning Inserts: For machining automotive brake discs, engine blocks, and large steel components.

- Milling Inserts: For specific roughing applications requiring high wear resistance.

- Threading & Grooving Tools: Ensuring long tool life in continuous cuts.

Equip Your Factory with the Best

Upgrade your tool performance with the technology used by industry leaders. The Ruideer RDE530L offers the perfect balance of capacity, coating quality, and operational safety.

Contact Ruideer today for a technical consultation on establishing your own CVD coating line.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!