Application

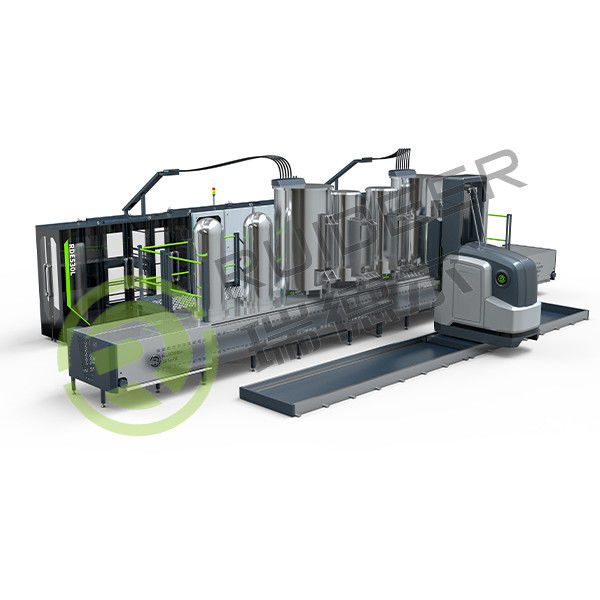

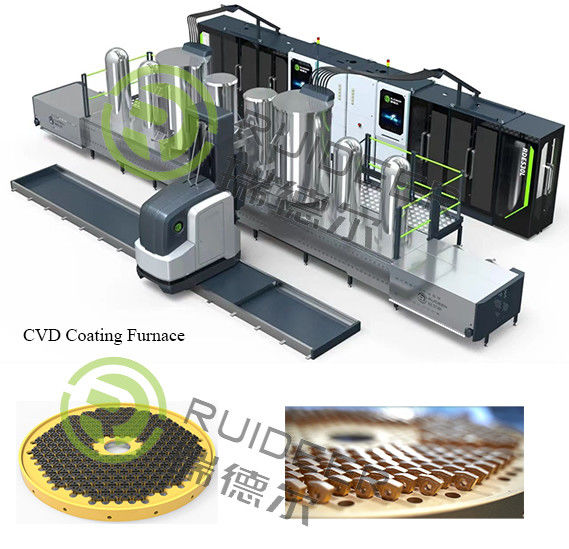

The CVD coating furnace is the main equipment for the production of cemented carbide coating tools. The cemented carbide coating tools are coated with a thin film on the surface of the cemented carbide substrate with good strength and toughness by chemical vapor deposition (CVD). It is obtained by layering refractory metal or non-metallic compound with good wear resistance. Carbide coated cutting tools have the characteristics of high surface hardness, good wear resistance, stable chemical properties, heat resistance and oxidation resistance, small friction coefficient and low thermal conductivity. When cutting, it can increase the tool life by more than 3-5 times than that of uncoated tools.

Assembly Group

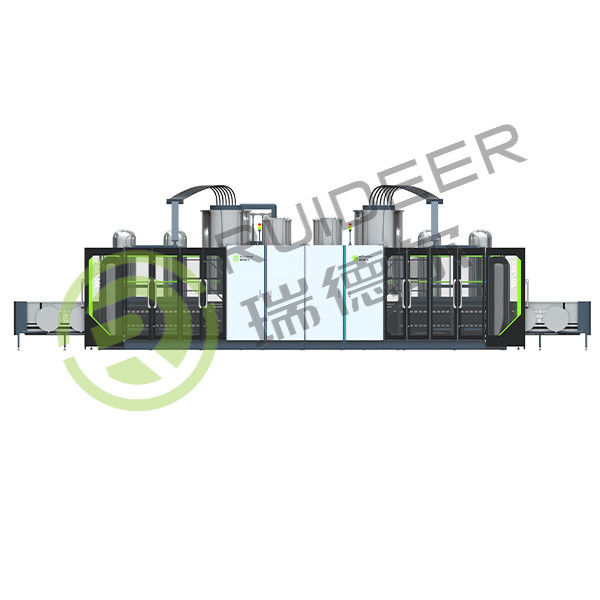

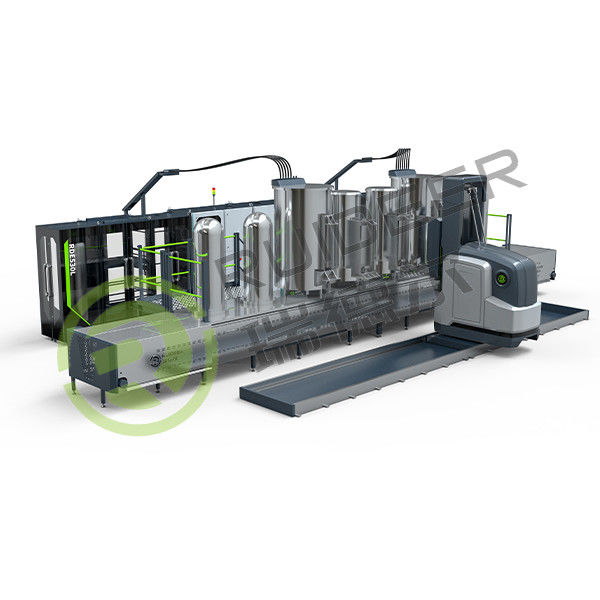

workbench

The workbench is made up of reaction chambers, heating covers, and cooling covers, and is composed of racks, platforms, reaction chamber bases, rotating cylinders, and rotating mechanisms.

reaction chamber

The reaction chamber is made of high-temperature-resistant and corrosion-resistant alloy steel, of which the cylinder is made by centrifugal casting.

heating cover

The heating cover is used to heat the reaction chamber and the workpiece in the reaction chamber, with a maximum heating temperature of 1050°C. The heating cover adopts five-zone heating with a power of 55KW. Each zone is equipped with a thermocouple with K graduation number for temperature detection. The heating element adopts a ceramic fiber heating module structure, the outer shell adopts ceramic fiber insulation, and the heating element is placed inside the ceramic fiber, which is convenient for maintenance and replacement. Among them, the heating element adopts imported Kanthal iron-chromium-aluminum alloy heating wire.

cooling cover

Cooling cover is used to reduce the heat radiation from the reactor and to cool the reactor after the painting process. In addition, safe lifting, transport and positioning of the reaction chamber can be achieved by means of cooling cover.

rail crane

The rail crane is used for lifting and transferring the reaction chamber, heating cover and cooling cover. Among them, the rail crane adopts the one-to-four mode, that is, one rail crane device can be used for lifting and transferring four CVD equipment. The hoisting and transfer of the reaction chamber, heating cover and cooling cover are all automatically controlled, which greatly improves automation of equipment.

condenser

Two condensers are used to cool the vented process gases from the reaction chamber and to condense wastes that are solid at room temperature, such as chlorides. The condenser is made of SUS316L stainless steel. In order to increase the cooling efficiency, the inside of the condenser adopts a "Z" shape structure.

Equipment Strengths

- Automatic Mode. According to the process settings, the individual components and processes are automatically controlled. Automatic control includes valve switch, process gas flow control, process liquid flow control, reactor pressure control, heating furnace and electric heating belt temperature control, etc., without human intervention in the whole process. The automatic operation process realizes automatic alarm processing. According to different alarm types, it will automatically enter the alarm mode to protect the products in the furnace. After the alarm is released, it can be manually restored to the state before the alarm.

- The process is monitored throughout the process, all sensor data and valve status are saved to historical data, which can be viewed at any time.

- Manual mode. There is a safety interlock, which automatically realizes the lock according to the gas type and temperature inside the reactor, and the reactor cannot be opened at will.The manual mode is set with one-button operation, such as vacuuming, H2 purge, N2 purge, etc., no need to manually move individual valves and vacuum pumps.

- The alarm data is automatically saved, and the historical data can be retrieved at any time.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!